Description

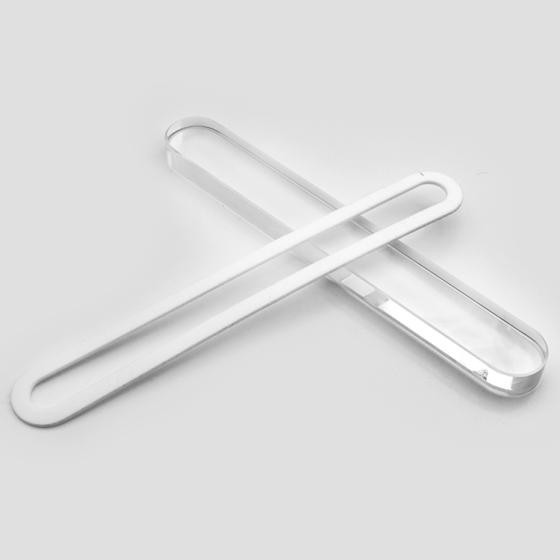

This type side edge is polished type .

Transparent flat gauge glass, also named

Transparent sight glass,

Transparent level glass

Transparent level gauge,

It is usually made of borosilicate glass and aluminosilicate glass.

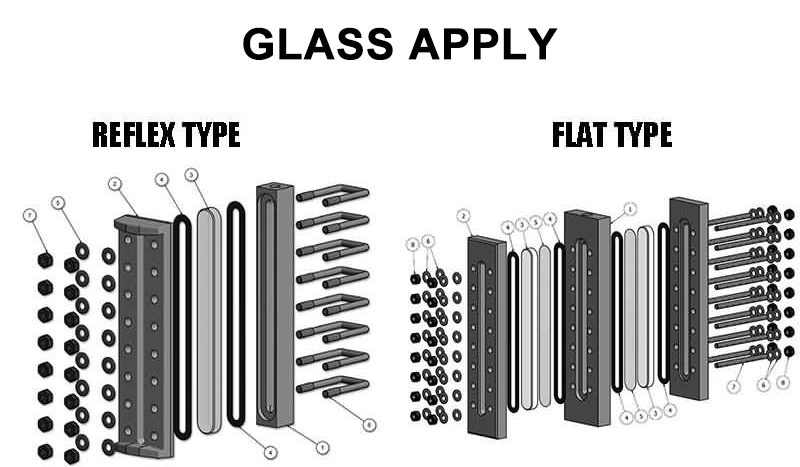

The glass is manufactured into the strip shape and used in boiler or some instruments for observing the liquid level.

Transparent type is also manufactured from "extra-hard" borosilicate glass. The surfaces on both sides are finely smooth and ensure optimal transparency.

A) One is as same with reflex Gauge Glasses,use molds to make the semi-finished products,afterwards,ground and polish the two side to ensure optimal transparency. By this manufacturing technique,the definition isn't good.

B)The other manufacturing technique is made of High Borosilicate sheet of 17mm thickness, cut the glass sheet according the detailed size and polish the side face for the smooth.This manufacturing technique glass is very clear,but the goods cost is higher.

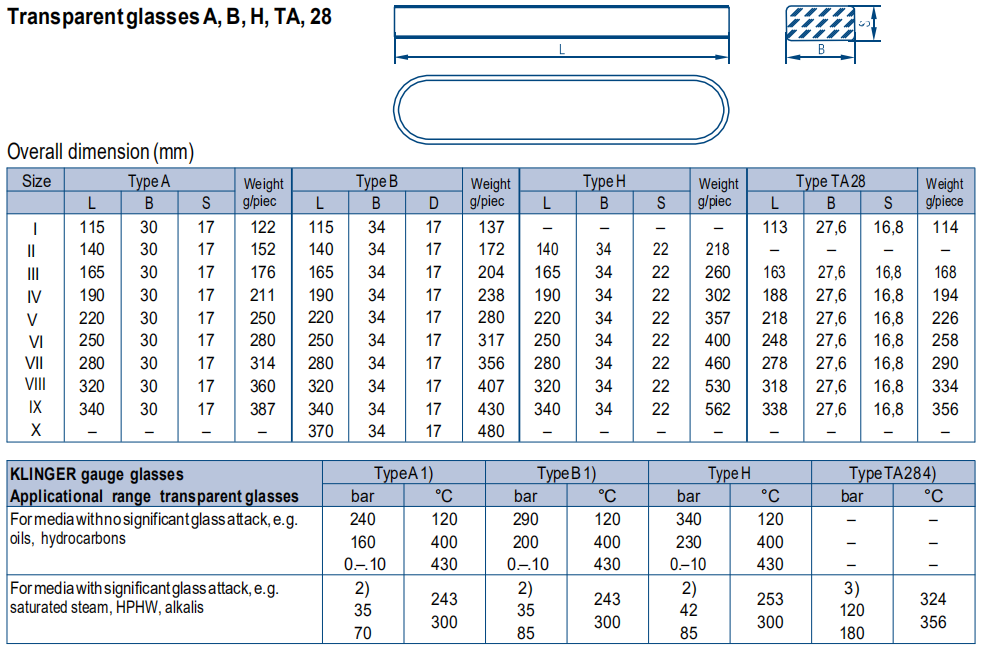

It can be used with all media at service conditions up to 6MPa and temperatures up to 430 degrees centigrade.

Applications:

In steam service above 35 bar and with media with a high pH-value.

Transparent glasses must be protected by a mica shield on the side facing the medium chamber. Transpar- ent glasses should always be chosen for contaminated, viscous or corrosive media. Within the given service limita- tions they may be used for all media ex- cept steam at pressures up to 340 bar or temperatures up to 400.°C.

Packing :

KLINGER gauge glasses are packed in individual cardboard boxes. In addition to the glass, each package contains a KLINGER sealing gasket and cushion gasket and forms a complete unit ready for installation.